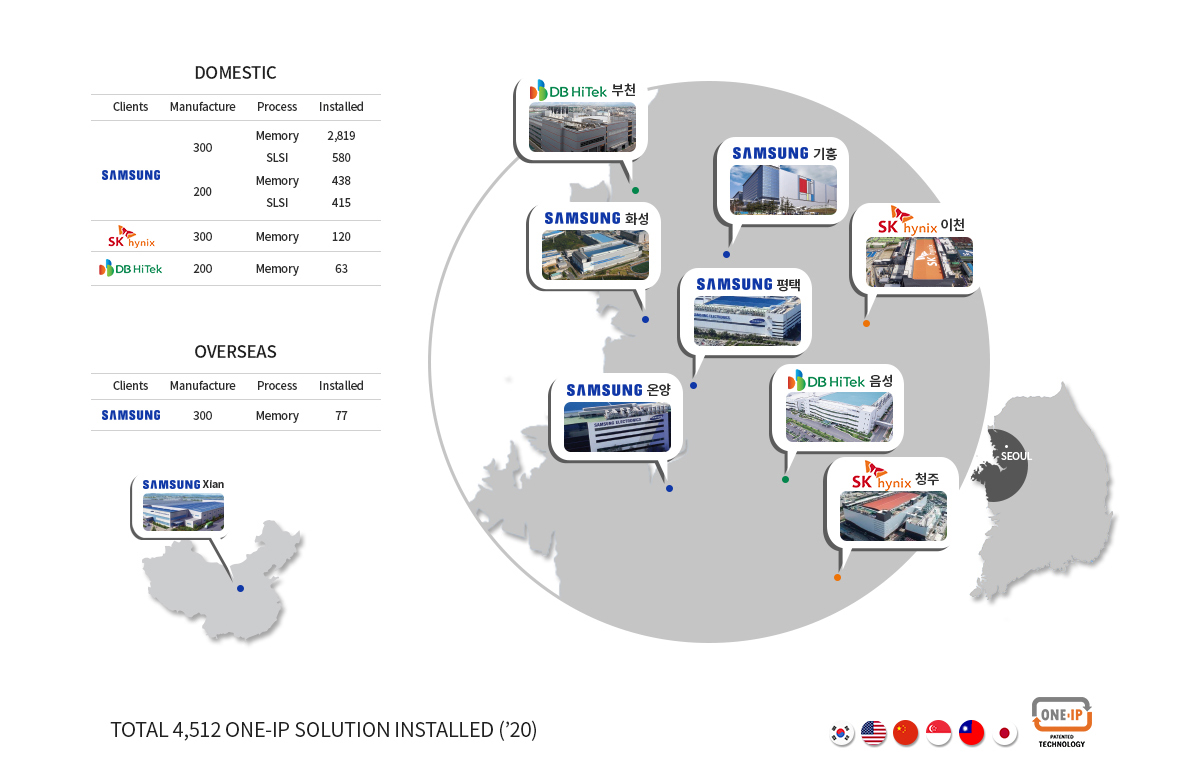

REMOTE CONTROL SYSTEM SOLUTION

Our remote control system solution portfolio covers the most of semiconductor-specific equipment from the industry.

Our remote control system solutions focus on providing world-class technology that improves efficiency, reduces costs, and empowers engineers to leverage their factory assets.

We also provide innovative IT solutions based on clients’ field needs such as a special dedicated controllers for certain equipment which was difficult to convert to remotely control.

The core technology of our solution enables converged video and data connectivity across remote desk and factory environment – from connected machines to screens.

Our solutions restructure the existing connections with our product to enhance the accuracy of your monitoring and controlling the equipment.

Our solution comes with the special smartness on connectivity.

With our so-called "ONE-IP" technology completed remote control structure wisely on the remoted facility without difficulties of IP management such as additional network installation.

| Manufacture | Processing | Maker | Model |

|---|---|---|---|

| MEMORY | Metal | APPLIED MATERIALS | ENDURA |

| TEL | UNITY EP | ||

| Etching | TEL | TEL_SCCM, TEL_DRM, TEL_MS, TEL_TE | |

| CVD | APPLIED MATERIALS | P-5000(2,3), CENTURA, ULITMA_X, ULTIMA_TE | |

| TEL | Clean Track_ACT(8) | ||

| Diffusion | APPLIED MATERIALS | CENTURA 5200 | |

| TEL | INDY, INDY PLUS, FORMULA, ALPHA 8SE, ALPHA 303i, NT333 | ||

| KE (KOKUSAI ELECTRIC) | CX3000-J1, CX3000-J2 | ||

| MATTSON TECHNOLOGY | STEAE AST 2800, AST 2900, AST 3000 | ||

| ASM | EPSILON 2000, EPSILON 2000 PLUS |

| Manufacture | Processing | Maker | Model |

|---|---|---|---|

| SLSI | Metal | APPLIED MATERIALS | ENDURA |

| TEL | UNITY EP | ||

| Etching | LAM RESEARCH | A9408 | |

| TEL | TEL_SCCM, TEL_DRM, TEL_MS, TEL_TE | ||

| CVD | APPLIED MATERIALS | P-5000(2,3), CENTURA, ULITMA_X, ULTIMA_TE | |

| TEL | Clean Track_ACT(8) | ||

| Diffusion | APPLIED MATERIALS | CENTURA 5200 | |

| TEL | INDY, INDY PLUS, FORMULA, ALPHA 8SE, ALPHA 303i, NT333 | ||

| KE (KOKUSAI ELECTRIC) | CX3000-J1, CX3000-J2 | ||

| MATTSON TECHNOLOGY | STEAE AST 2800, AST 2900, AST 3000 | ||

| ASM | EPSILON 2000, EPSILON 2000 PLUS |

| Manufacture | Processing | Maker | Model |

|---|---|---|---|

| MEMORY | Clean/Photo | TEL | CELLESTA-I, NS300+ (300) |

| Etching | TEL | Clean Track_ACT(12) | |

| Diffusion | TEL | INDY, INDY PLUS, FORMULA, ALPHA 8SE, ALPHA 303i, NT333, TRIASE GENUINE | |

| TEL | CX3000-J3, CX-5000 |

| Manufacture | Processing | Maker | Model |

|---|---|---|---|

| SLSI | Clean/Photo | TEL | CELLESTA-I, NS300+ (300) |

| Etching | TEL | Clean Track_ACT(12) | |

| Diffusion | TEL | INDY, INDY PLUS, FORMULA, ALPHA 8SE, ALPHA 303i, NT333, TRIASE GENUINE | |

| TEL | CX3000-J3, CX-5000 |

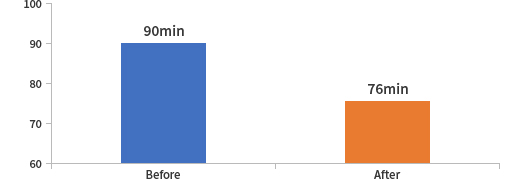

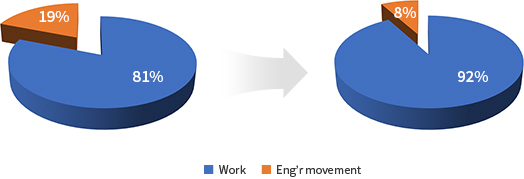

| Financial performance analysis | Fab engineers’ work efficiency analysis |

|---|---|

※ 271 cases occurred in the Diffusion process in year 2015. After RCS application, 14 mins (90 mins – 76 mins) action time decreased. |

※ After RCS application, 3.5 km decrease in distance traveled by an engineer in the fab. 6.3 Km/Daily

2.8 Km/Daily Average 54 mins travel time saved daily per person 2.8 Km/Daily Average 54 mins travel time saved daily per person

Assuming 100 engineers working in fab, 100 men × 54 mins = 5,400 mins which is equal to working hours of 11.25 engineers per a day. |